Brakes are among the most vital car components that must be in good status all the time. The brake pad wear indicator is another component that may not be considered by many car owners, yet it is very important in brake maintenance. In this article, you will get to know a lot about brake pad wear indicators, including their working, the advantages of brake pad wear indicators, and many more. By the end of the page, we will understand these useful gizmos and why they are important for our cars.

What are Brake Pad Wear Indicators?

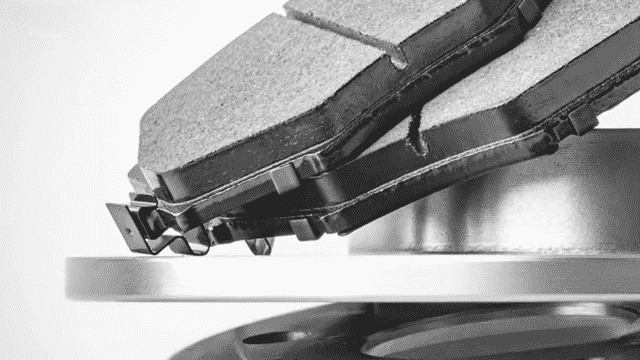

A brake pad wear indicator is an additional small component fixed to the brake pad to notify the driver when the brake pads are almost worn out. These indicators are intended to raise the alarm before brake failure occurs, which is dangerous and can amount to quite a lot of money.

Types of Brake Pad Wear Indicators

Mechanical Indicators

Mechanical indicators are the easiest type of wear indicators to measure. They normally incorporate a thin metal plate joined to the brake pad. As the brake pad deteriorates, the tab rubs against the brake rotor and makes a squealing noise, thus letting the driver know that the brake pad is almost worn out.

Electronic Indicators

Electrical indicators are enhanced, and sensors are used to gauge the thickness of the brake pad. As the pads wear to a certain limit, the senders switch on the brake light on the vehicle’s dashboard, informing the driver that it is time for a change of brake pads.

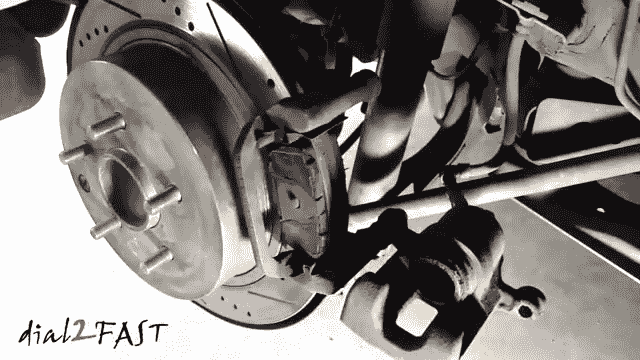

How Brake Pad Wear Indicators Work

Mechanical Indicators

Contact-based mechanical wear indicators are used because of their mode of operation. At the shallow thickness of the brake pad material, the metal tab rubs onto the rotor and further makes a distinctive screeching sound. This sound indicates that the brake pads are worn out and must be changed.

Electronic Indicators

Originally, they were electronic, using sensors placed on the brake pads. These sensors detect the thickness of the pad/throttle and translate this into a signal fed into the vehicle’s microprocessor. When brake pads are worn to a specified thickness, the warning light on the truck’s dashboard turns on, showing that the brake pads require service.

Benefits of Using Brake Pad Wear Indicators

Safety

There is concrete evidence that the use of brake pad wear indicators has a primary advantage since it serves as a safety feature. The above examples are early warning indicators that assist in preventing brake failure so as to allow for the effective stopping of the vehicle.

Cost Efficiency

Considering brake pads’ reconditioning service before they wear out can be economical. Old brake pads may cause a scrubbing effect on the brake rotors, which in turn leads to costly repairs. These are additional costs that the use of indicators can assist you in preventing.

Maintenance Ease

This means that through the wear indicators, one does not need to assume when the brake pads are due for change. This makes maintenance slightly easier and guarantees that the brakes are always working.

Signs Your Brake Pads Need Replacement

- Common Indicators

- Squealing or squeaking noise

- Grinding sound when braking

- Reduced braking efficiency

- Blinking symbol or sign on the instrument cluster (for digital signals).

Importance of Timely Replacement

The signal indicating the reduced thickness of the brake pads should not be dismissed as it foretells a failure and more expensive operations. Regular updates are essential to ensure that the vehicles are safe and effective on the road.

Installation of Brake Pad Wear Indicators

DIY Installation

To those interested in car mechanics, a number of companies offer mechanical brake pad wear indicators, and the process of installing them may be a do-it-yourself project. But the installation, especially for the first time, should be done according to the manufacturer’s instructions to avoid problems.

Professional Installation

In the case of electronic indicators or if the String-Trimmer is counterintuitive for the shopper, professional installation should be done. Employment assurances also make a lot of sense, and only professional mechanics with tools have the capability to install the indicators appropriately and or ensure they work as required.

FAQs

What happens if I ignore my brake pad wear indicator?

Ignoring the indicator can lead to brake failure and more costly repairs.

How often should I check my brake pads?

It’s advisable to check them every six months or during regular vehicle maintenance.

Are electronic indicators better than mechanical ones?

Electronic indicators provide more precise warnings but are generally more expensive.

Can I install a brake pad wear indicator myself?

Mechanical indicators can be DIY, but electronic ones are best installed by professionals.

How do I know which brake pad wear indicator to buy?

Consider your vehicle type, driving conditions, and budget. Research and choose a reputable brand.