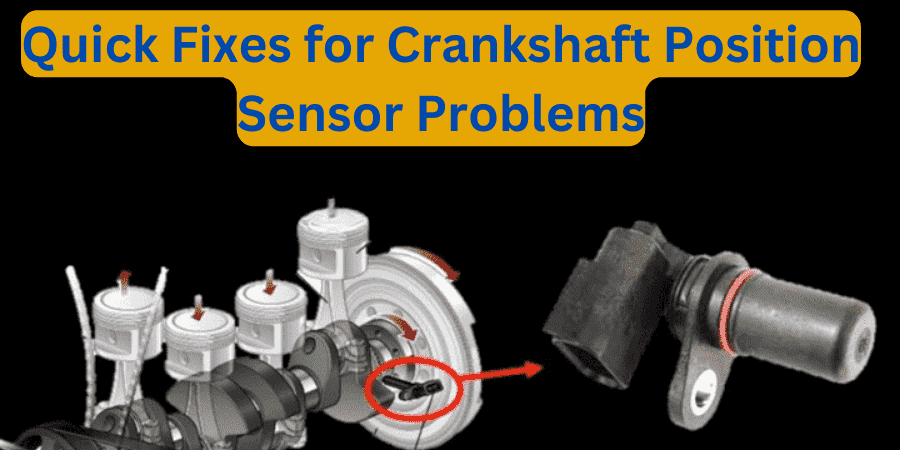

The crankshaft position sensor is responsible for almost all aspects of your car as far as the engine is concerned. This small yet powerful sensor checks and keeps track of the position of the crankshaft and its angular velocity and relays all this to the ECU. What is the impact when it starts to falter? It’s important to identify the signs and understand where to put quick remedies that would assist in reducing agony and ensure that the vehicle is operational during the search for a long-term solution.

What is a Crankshaft Position Sensor Used for?

A crankshaft position sensor is an electronic switch that identifies the crankshaft position and its rotary speed. This data is important to the ECU to enable it to adjust the ignition time and fuel supply to enhance the performance of the vehicle’s engine.

How Does It Work?

The specific type produces a signal as a result of the degree and the velocity of the crankshaft. It is then transferred to the ECU, which regulates the ignition and the fuel injection rate. This causes engine issues when the ECU cannot receive accurate data from the faulty sensor.

Classic Source of Failure of the Sensor

Crankshaft position sensors can fail due to several reasons:

- The heat from the engine and the heat of the fluids

- A short, wiring problems, or any other electrical problems in the house

- Material impact from plowing or physical contact with objects

- Aging in time

Diagnosing Crankshaft Position Sensor Problems

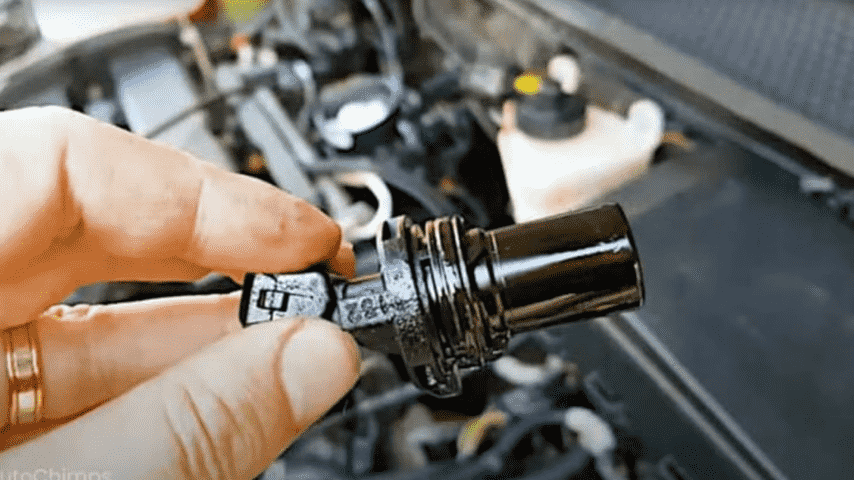

Visual Inspection

This process can commence with a general visual inspection of the part. Identify the areas where the shock sensor might be physically damaged, have connection problems, or be corroded.

Using an OBD-II Scanner

An OBD-II scanner can interface with the ECU of a vehicle in order to read the error codes. Some frequently used DTCs are P0335: Crankshaft Position Sensor A Circuit Malfunction and P0336: Crankshaft Position Sensor A Circuit Range/Performance.

Checking the Wiring and Connections

Faulty wiring or loose connections can mimic sensor failure. Inspect the wiring harness and connectors for any signs of damage or looseness.

Temporary Fixes for Crankshaft Position Sensor Problems

Temporary Fix 1: Cleaning the Sensor

Tools Needed:

- Screwdriver set

- Cleaning solvent

- Microfiber cloth

Step-by-Step Cleaning Process

- Disconnect the battery to ensure safety.

- Locate the crankshaft position sensor (refer to your vehicle’s manual).

- Carefully remove the sensor using a screwdriver.

- Clean the sensor with a solvent and microfiber cloth to remove dirt and debris.

- Reinstall the sensor and reconnect the battery.

Temporary Fix 2: Securing Loose Connections

Identifying Loose Connections:

Inspection should be conducted on all the connectors around the sensor, and diligently check if they are loose or corroded.

Pull the wires slightly and wiggle them to ensure that they are well-fixed.

Tools and Steps to Secure Them

- Disconnect the battery.

- Clean the connectors with an electrical contact cleaner.

- Twist the excess lead around the connection and secure it with round nose pliers.

- Reconnect the battery.

Temporary Fix 3: Using Heat Protection

Importance of Heat Protection

High temperatures are not good for the sensor’s head or its wires; therefore, extreme heat must be avoided. Various protective implements can be worn to protect the sensor, and they can temporarily slow down the rate at which the sensor is damaged due to heat.

How to Apply Heat Shields or Sleeves

- You can buy heat shields or sleeves at the auto part store.

- Disconnect the battery.

- Heat protection is placed on the sensor and its wire connection.

- Then, Lock it with Zip ties or clamps.

- Reconnect the battery.

Temporary Fix 4: Adjusting the Sensor Position

Tools Needed:

- Screwdriver set

- Vehicle’s service manual

Step-by-Step Adjustment Process

- Disconnect the battery.

- Consult the service manual to find out where the sensor is and how it should be configured.

- It is a good idea to relax the sensor mounting bolts a little.

- If necessary, modify the position of the employed sensor.

- Tighten the bolts and connect back the battery as indicated before.

DIY vs. Professional Help

Advantages and disadvantages

Pros:

- Cost-effective

- Immediate solution

- Learning experience

Cons:

- It is necessary to underline the temporary nature of the fixes

- Possibility of aggravating the existing problem due to improper handling

When to Call a Professional

If the mentioned temporary remedies do not help troubleshoot the problem, or you are hesitant to do it yourself, it is advisable to consult a professional. Constant problems might be a sign of a critical issue that requires the attention of a professional.

Final Words

Fixing crankshaft position sensor problems can be a discouraging task, though there are a lot of things that one can do to manage the problem before getting a technician to repair it. Usually, maintenance should be done regularly, and the parts to be used have to be of a high standard to avoid future complications. However, do not forget that although such fixes are handy, it is not impossible to ask for professional assistance.

FAQs

What are the signs of a bad crankshaft position sensor?

Common signs include engine misfires, stalling, difficulty starting, and a check engine light.

Can I drive with a faulty crankshaft position sensor?

It’s possible but not recommended, as it can lead to further engine damage and unsafe driving conditions.

How much does it cost to replace a crankshaft position sensor?

The cost can vary widely but generally ranges from $100 to $300, including labor.

Can a bad crankshaft position sensor cause a no-start condition?

Yes, a faulty sensor can prevent the engine from starting as it disrupts the ignition timing and fuel injection.

How often should the crankshaft position sensor be checked?

Inspecting it during regular maintenance checks or if you notice any related symptoms is good practice.