Are you confused about which wire to use for your 100-amp service? Choosing the right one is critical for safety. Specifications that may define a wire include the type and amount required. Sometimes, it is too much for one person to handle for so long. Perhaps it is about time you had all those issues concerning your electrical system sorted and secured…

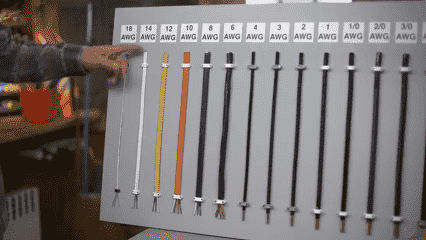

Remember That: For 100 amp service, typical wire sizes are 4 AWG or 2 AWG for copper wiring and 2 AWG, 1 AWG, or 1/0 AWG for aluminium or copper-clad wiring. These sizes are also suitable for immediate burial.

When selecting a 100-amp service wire size, keep in mind that a 100-amp circuit at 240V can handle up to 24,000W of power.

Understanding Electrical Wire Sizes

What is Wire Gauge?

Wire gauge is the thickness of a wire. It is measured using the numerical system in which a lower number shows that a wire is thicker, and a higher number shows that a wire is thinner. For example, 12 gauge is thicker wire, and 24 gauge is thinner wire because 12 gauge wire carries more electricity than 24 gauge wire.

How Wire Size Affects Electrical Systems?

Wire size affects electrical systems by determining how much current flows in the wire safely. Thicker wires can handle more current without overheating, and this is suitable for high-power devices. In comparison, thinner wire is used only in low-power devices if we use the wrong sizes, causing overheating, voltage drops, or even fires. For example, a thick 12 gauge is used for heavy-duty appliances, while a thin 22-gauge wire is fine for small electronics.

Where do people use 100 AMP Service?

The question is whether the 100 amp service is enough for your house. It depends on house size but is commonly used in residential homes and small commercial buildings.100 amp service operates at a standard voltage of 240 volts.

These services are commonly used in older houses with limited appliances. But nowadays, larger houses with a combination of electric and gas use 150 AMP or 200 AMP services.

Moreover, the 100 AMP service is currently used temporarily. You can see its use everywhere.

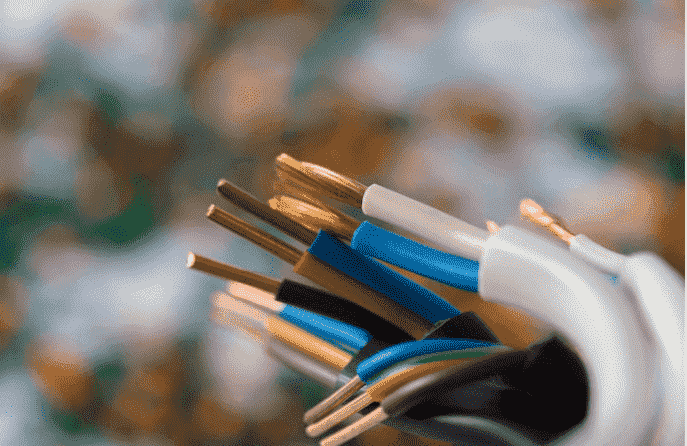

Types of Wires for 100 Amp Service

When selecting wires for a 100-amp service, choosing the perfect type and size is important to ensure safety, compliance with electrical codes, and proper functioning.

Some common types of wire for 100 AMP service panels are both copper and aluminium wires.

Types of Copper Wires:

The copper wire size for 100-amp Service is 4 AWG. Some types of copper wire are THHN/THWN Wire, XHHW Wire, USE-2/RHH/RHW-2 Wire, and MC Cable (Metal Clad Cable).

- 1. THHN/THWN Wire( Nylon-coated): Common use in residential, commercial, and man-made installations. It offers good protection against heat and moisture.

- 2. XHHW Wire( Cross-linked polyethylene (XLPE)): It is suitable for wet and dry locations and offers better durability against environmental factors.

- 3. USE-2/RHH/RHW-2 Wire is commonly used for underground installation and where extra durability is needed. It is suitable for both direct burial and exposed burial.

- 4. MC Cable (Metal Clad Cable): MC Cable contains multiple conductors, including a ground wire encased in a metal sheath. It is used in commercial and industrial settings and is covered with a metal sheath.

Types of Aluminum Wires

The aluminum wire size for 100-amp Service is 2 AWG. Here are some common types:

1. USE-2 (Underground Service Entrance) Wire: Wire is used for underground service with high durability and moisture resistance.

2. XHHW-2 (Cross-linked High Heat-resistant Water-resistant) Wire: It is suitable for wet and dry locations, providing superior heat and moisture resistance and protection from environmental factors.

3. SER (Service Entrance Cable): Used for above-ground service entrance of the application. And the cable is jacketed for extra protection.

100 Amp Wire Size Chart

| Material | Temperature Rating | Length | Wire Gauge (AWG) |

| Copper | 60°C (140°F) | Up to 100 ft | 3 |

| Copper | 60°C (140°F) | 100-150 ft | 2 |

| Copper | 60°C (140°F) | 150-200 ft | 1 |

| Copper | 75°C (167°F) | Up to 100 ft | 3 |

| Copper | 75°C (167°F) | 100-150 ft | 2 |

| Copper | 75°C (167°F) | 150-200 ft | 1 |

| Copper | 90°C (194°F) | Up to 100 ft | 4 |

| Copper | 90°C (194°F) | 100-150 ft | 3 |

| Copper | 90°C (194°F) | 150-200 ft | 2 |

| Aluminum | 60°C (140°F) | Up to 100 ft | 1 |

| Aluminum | 60°C (140°F) | 100-150 ft | 1/0 |

| Aluminum | 60°C (140°F) | 150-200 ft | 2/0 |

| Aluminum | 75°C (167°F) | Up to 100 ft | 1 |

| Aluminum | 75°C (167°F) | 100-150 ft | 1/0 |

| Aluminum | 75°C (167°F) | 150-200 ft | 2/0 |

| Aluminum | 90°C (194°F) | Up to 100 ft | 2 |

| Aluminum | 90°C (194°F) | 100-150 ft | 1 |

| Aluminum | 90°C (194°F) | 150-200 ft | 1/0 |

100 Amp Wire Size Chart in mm and inches

| Material | Length | Wire Gauge (AWG) | Diameter (mm) | Diameter (in) |

| Copper | Up to 100 ft | 3 | 5.827 mm | 0.229 in |

| Copper | 100-150 ft | 2 | 6.544 mm | 0.258 in |

| Copper | 150-200 ft | 1 | 7.348 mm | 0.289 in |

| Copper | Up to 100 ft | 3 | 5.827 mm | 0.229 in |

| Copper | 100-150 ft | 2 | 6.544 mm | 0.258 in |

| Copper | 150-200 ft | 1 | 7.348 mm | 0.289 in |

| Aluminum | Up to 100 ft | 1 | 7.348 mm | 0.289 in |

| Aluminum | 100-150 ft | 1/0 | 8.252 mm | 0.325 in |

| Aluminum | 150-200 ft | 2/0 | 9.266 mm | 0.365 in |

| Aluminum | Up to 100 ft | 1 | 7.348 mm | 0.289 in |

| Aluminum | 100-150 ft | 1/0 | 8.252 mm | 0.325 in |

| Aluminum | 150-200 ft | 2/0 | 9.266 mm | 0.365 in |

This chart helps you choose the correct wire size for a 100-amp circuit based on length, temperature rating, and material, with diameter conversions to metric and imperial units.

NEC Recommendations

The National Electrical Code (NEC) tells us what size wires to use based on the service’s power. The NEC usually says to use 4 AWG copper wires or 2 AWG metal wires for a 100-amp service.

Step-by-Step Installation Guide

- 1. Turn Off the Power: Remember that when starting the work, all the power is turned off.

- 2. Install the Meter Base: The base of the meter is attached outside the houses.

- 3. Run the Conduit: Connect the meter base to the main breaker panel with the conduit.

- 4. Pull the Wire: Use the pipe to pull the right wire through it.

- 5. Connect to the Breaker Panel: Connect the wires to the main breaker and ground them as per code requirements.

- 6. Inspect and Test: Before turning on the power again, have a qualified inspector review your work and test the system.

Final Thought

Finally, while choosing a wire to delineate the size that is permission for the 100 amp service, the right gauge wire is important to avoid circuit complications or malfunctions. Nominally, it is advised that one use an AWG 2-gauge copper or an AWG 1/0 aluminium conductor wire. Selecting the appropriate wire size avoids overloading of heat generation and allows the frequently occurring flaws in the electric systems, which results in the turbulent and unsafe working of the system. In general, it is always advisable to seek the services of a professional electrician when there is a special need or local code.

FAQs

What are the repercussions of getting the wrong wire size?

Choosing the incorrect wire gauge is detrimental as it can result in the production of heat, electrical fires, and equipment destruction. They can also result in reduced voltage, which may affect the overall performance of your electrical system or even lead to some of the household appliances failing to work as expected.

What if the service factor is 100 amps above the code allowable? What type of wire can I use, and is aluminum wire permissible?

Yes, you can use aluminum wire for a 100-amp service as long as it is/the application is as per code requirements. An AWG 1/0 or seven conductors of aluminum conductor steel reinforced (ACSR) or any other conductor of a similar gauge is desired. Make sure that wattage dropped connections are correctly rated for aluminum to avoid corrosion and for safety purposes.

What are some indications that the electrical system is overloaded?

Beware of the following signs: tripping breakers by a heavy current, blinking or hazy-looking bulbs, hum from outlets or switches, and the smell of burning. One might also experience outlets and switches giving warm or discolored light.

To what extent is electrical wiring a standard design?

You should inspect your electrical wiring every 3 – 5 years, depending on the situation. Nevertheless, buildings with more than fifty years of construction or those structures often associated with electrical problems require more regular inspection. This will ensure that facilities are checked for possible electrical malfunctions and threats to safety.